Flanges General

A flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

TYPES OF FLANGES

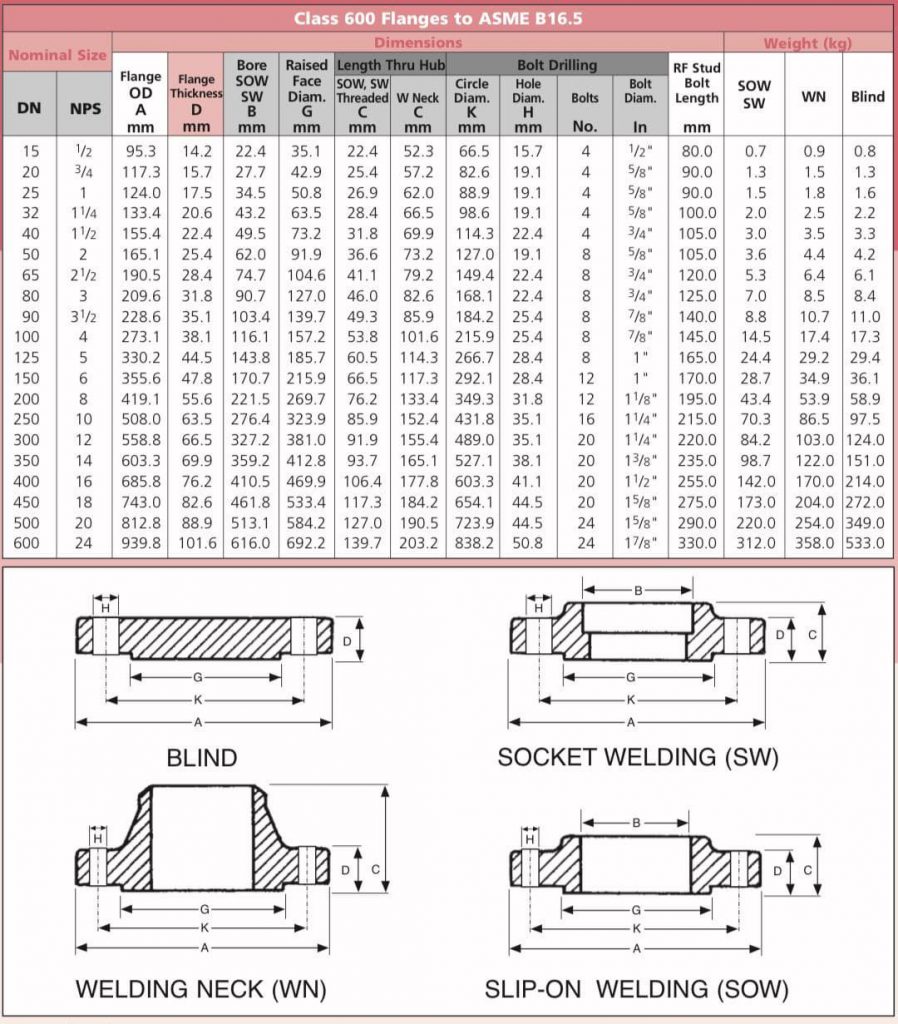

• Welding Neck Flange

• Long weld neck

• Slip On Flange

• Socket Weld Flange

• Lap Joint Flange

• Threaded Flange

• Blind Flange

• Orifice Flange

• Spade and spacer

• Spectacle blind

Materials for Flanges

Materials used by PTS:

• CARBON STEEL

• STAINLESS STEEL (304,316L,321,347)

• A350 (LF2,LF3)

• A694 grade 42,52,60,70

• INCONEL

• MONEL

Size :

1/2″ – 60″ INDUSTRIAL FLANGES

FLANGE SPECIFICATIONS

Standard

….

Notice :

The current ANSI / ASME/API flange specifications of B16.5 and B16.47(A & B), API 6A trace their roots to the old B16.1 specification from decades past, which consisted primarily of cast iron. This specification in turn was developed from the original AESC / ASA committee B16 in the 1920s.

For reference, head on over to:

*ANSI stands for “American National Standards Institute” and more information can be found on their website: https://www.ansi.org/

**ASME Stands for “American Society of Mechanical Engineers” and more information can be found on their website: https://www.asme.org/

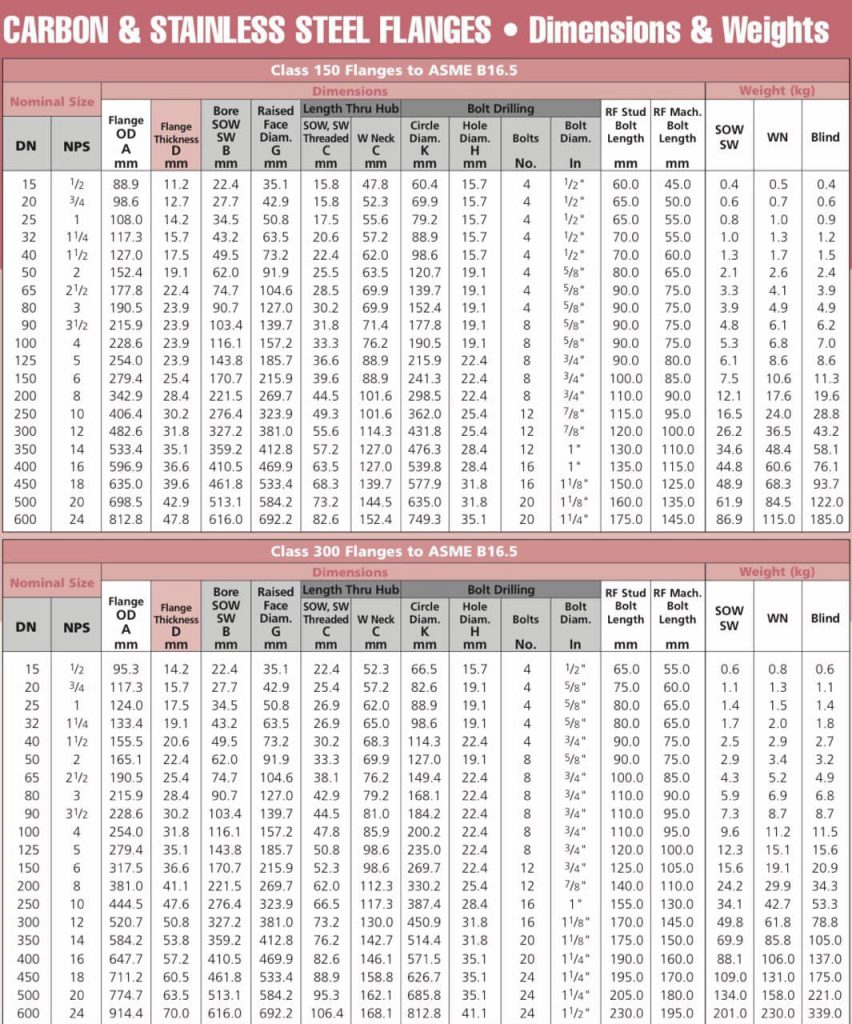

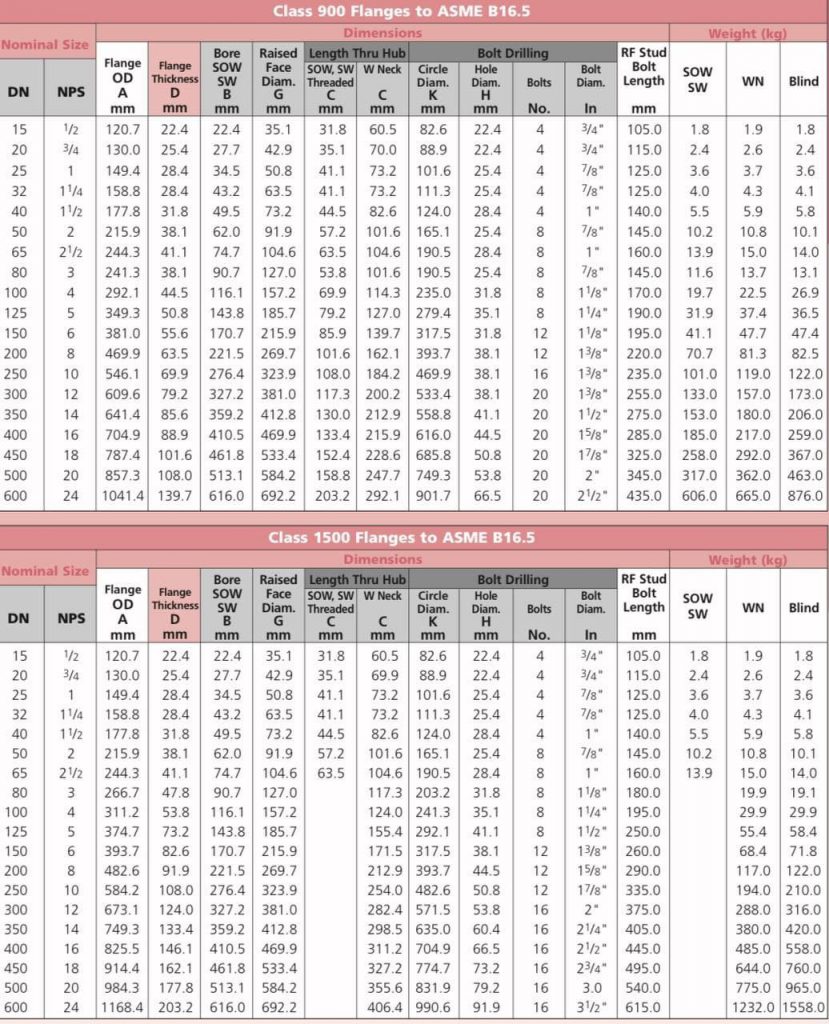

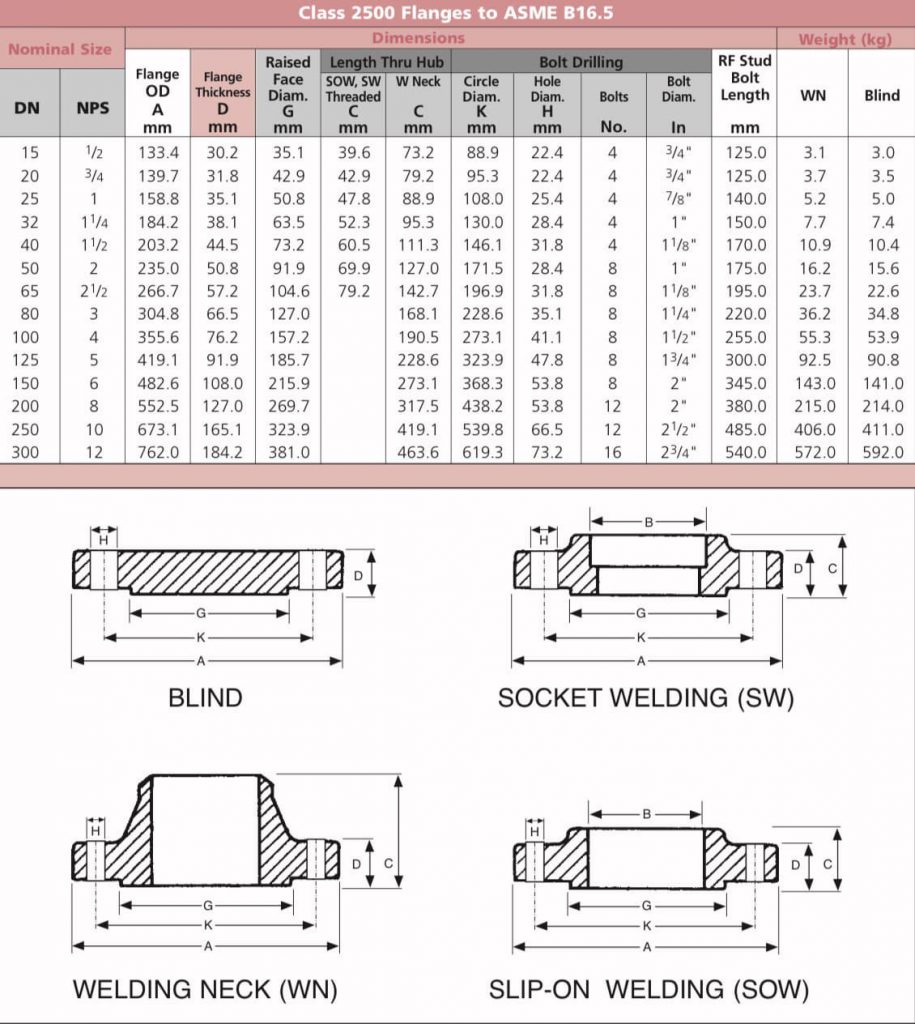

Pressure Classes of Flanges

Forged steel flanges ASME B16.5& ASME B16.47 A-B & API 6A are made in seven primary Pressure Classes:

150 – 300 – 400 – 600 – 900 – 1500 – 2500 -3000-5000-10000-15000