Standard Gasket Material

- CARBON STEEL (inner & outer ring)

- 316 STAINLESS STEEL

- 316L Stainless Steel

- 304 Stainless Steel

- 304L STAINLESS STEEL

- MONEL

- INCONEL(625,725,825)

- LOW CARBON STEEL

RING TYPE JOINT GASKETS

Ring type joints are primarily used in the oil, gas, petrochemical and chemical industries for sealing of flange joints exposed to high temperatures (up to 1000 °C) and pressures (up to 1500 bar). RTJs are offered in two basic shapes: oval or octagonal, possibly in other shapes. A wide range of materials provides the metal gaskets with excellent sealing performance under various conditions.

Style R

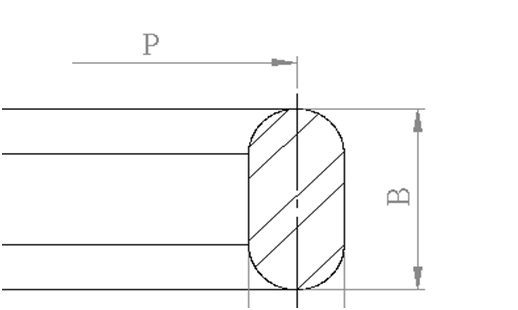

R (oval):

The octagonal shape of R type is more accurate than oval shape (indimensions and surface finish) because it consists of straight surfacesonly. These gaskets comply with API 6A or ASME B16.20 to suit API 6B.

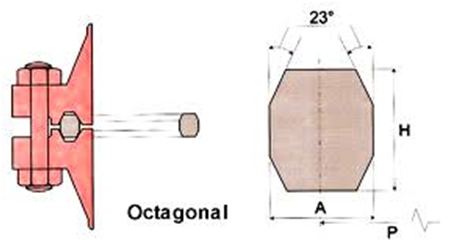

R (octagonal) :

The octagonal shape of R type is more accurate than oval shape (in dimensions and surface finish) because it consists of straight surfaces only. These gaskets comply with API 6A or ASME B16.20 to suit API 6B

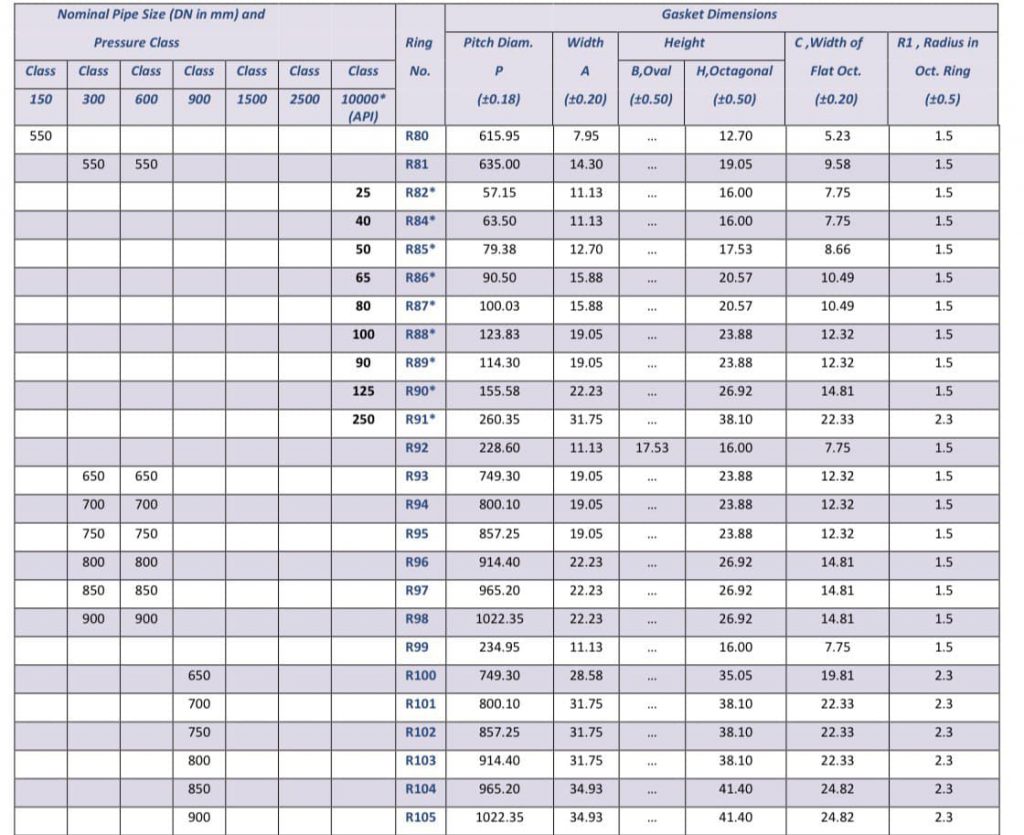

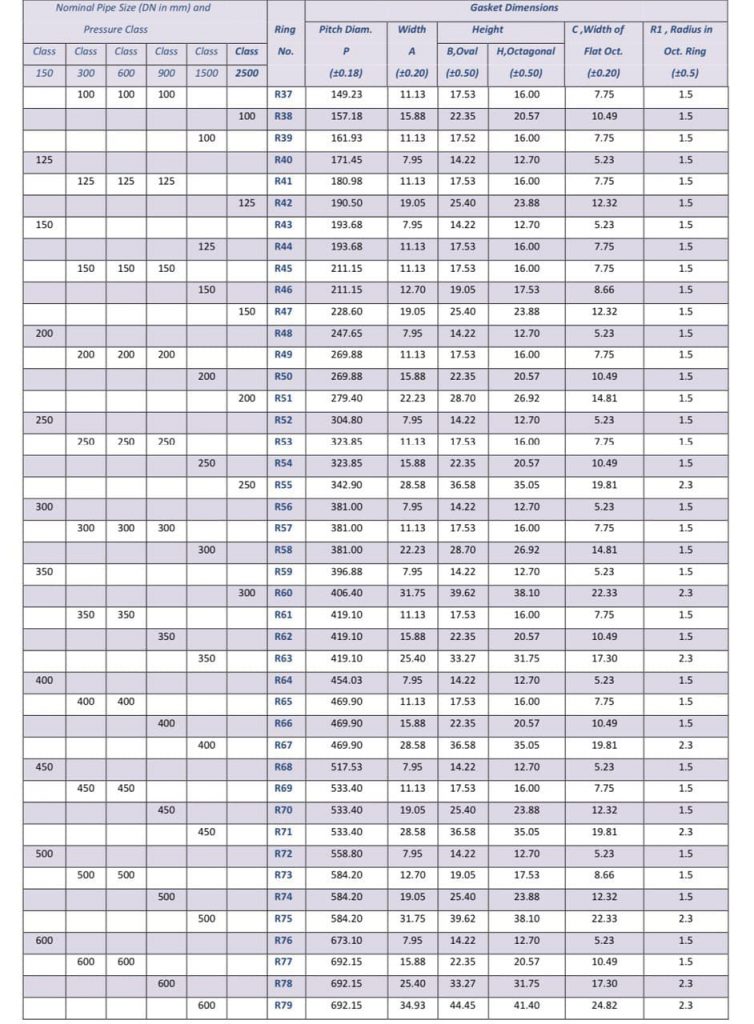

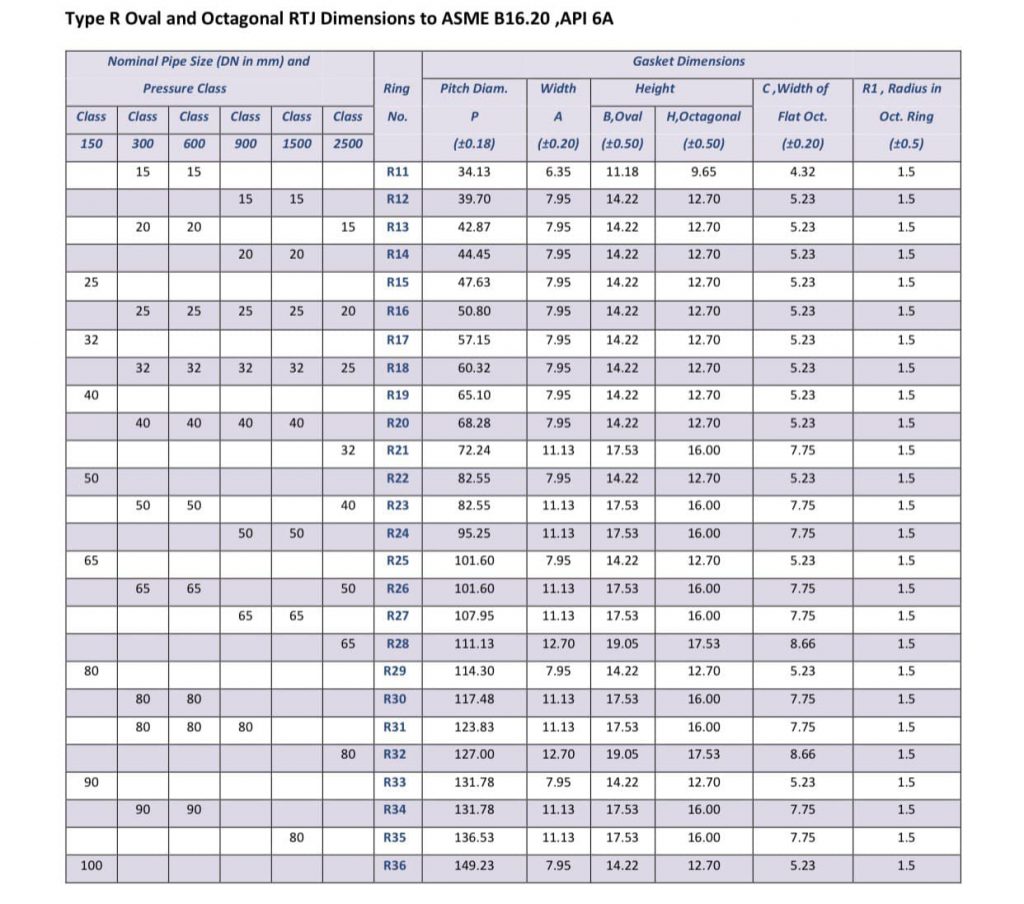

Type R Oval & Octagonal RTJ Dimensions

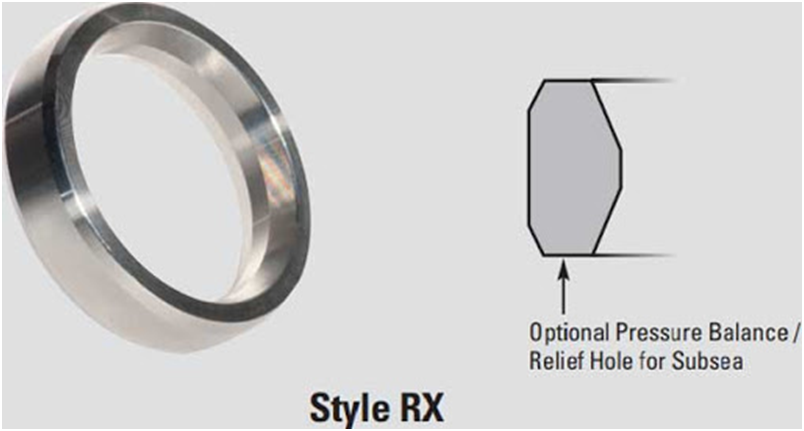

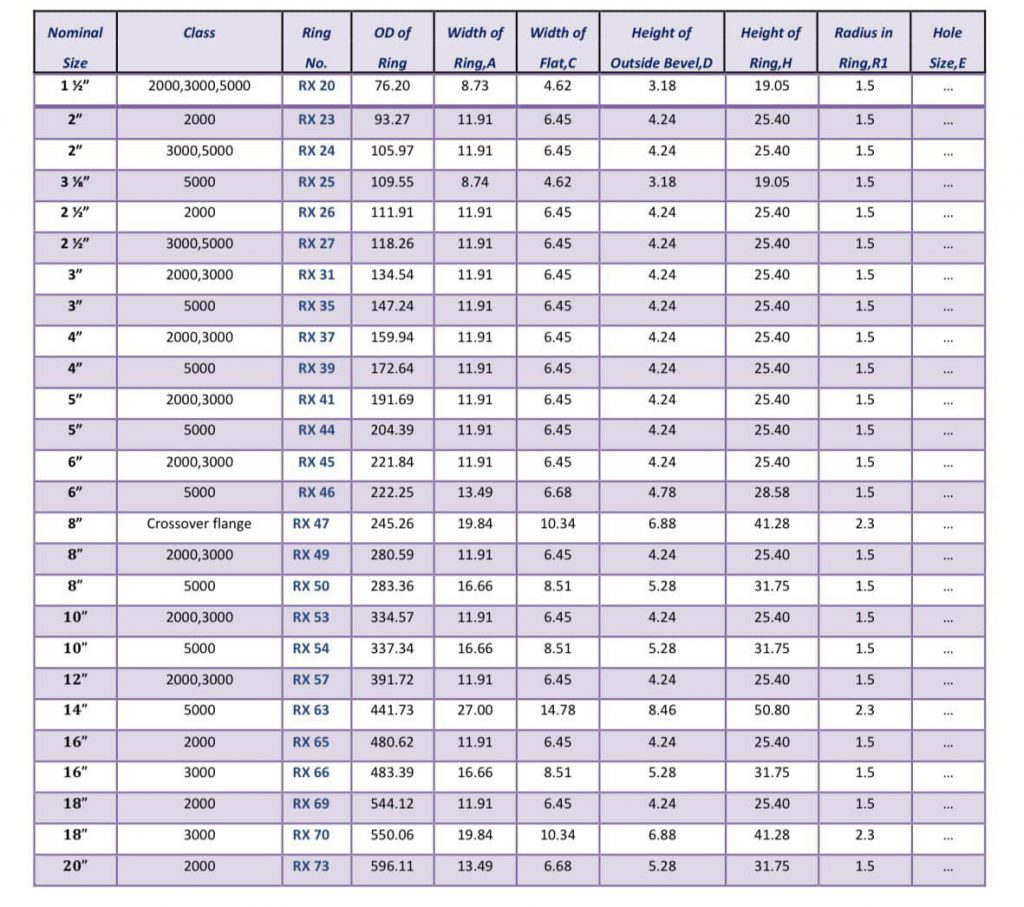

Style RX :

The RX is a pressure energized version of the R octagonal gasket and fits the R type flat bottomed groove. The RX has an increased height and utilizes the internal system pressure to energize and improve the seal an internal pressure increase. The RX type RTJ gasket is manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges.

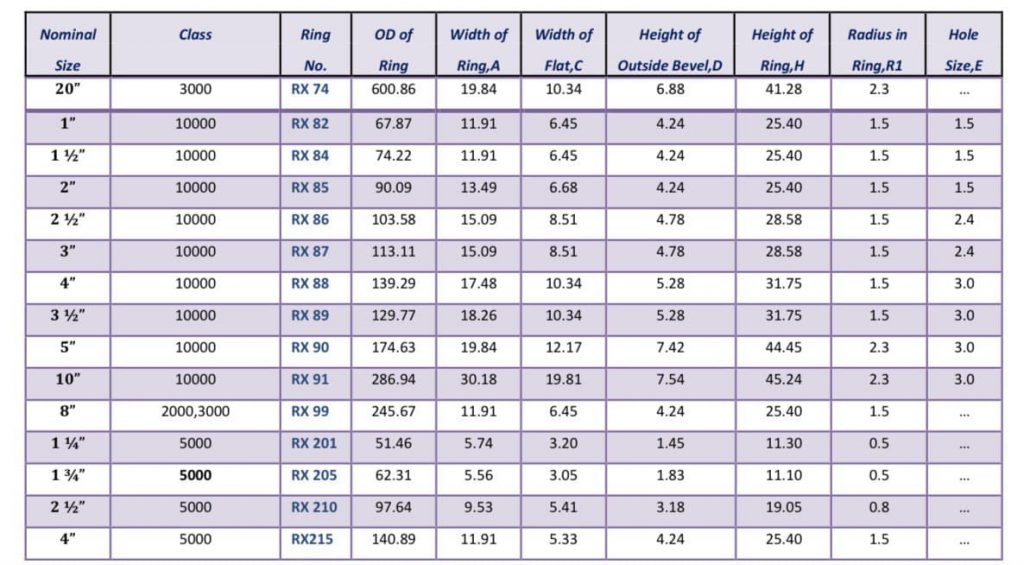

Type RX RTJ Dimensions

Style BX

The style BX energized ring type joints manufactured in accordance with API 6A are designed for use on pressurized systems up to 20,000 psi

When correctly fitted this style BX gasket allows virtual face to face contact of the flange faces which means that the gasket is fully trapped and both the inner and outer diameters

all BX gaskets incorporate pressure balance hold to ensure equalization of pressure which may be trapped in the grooves

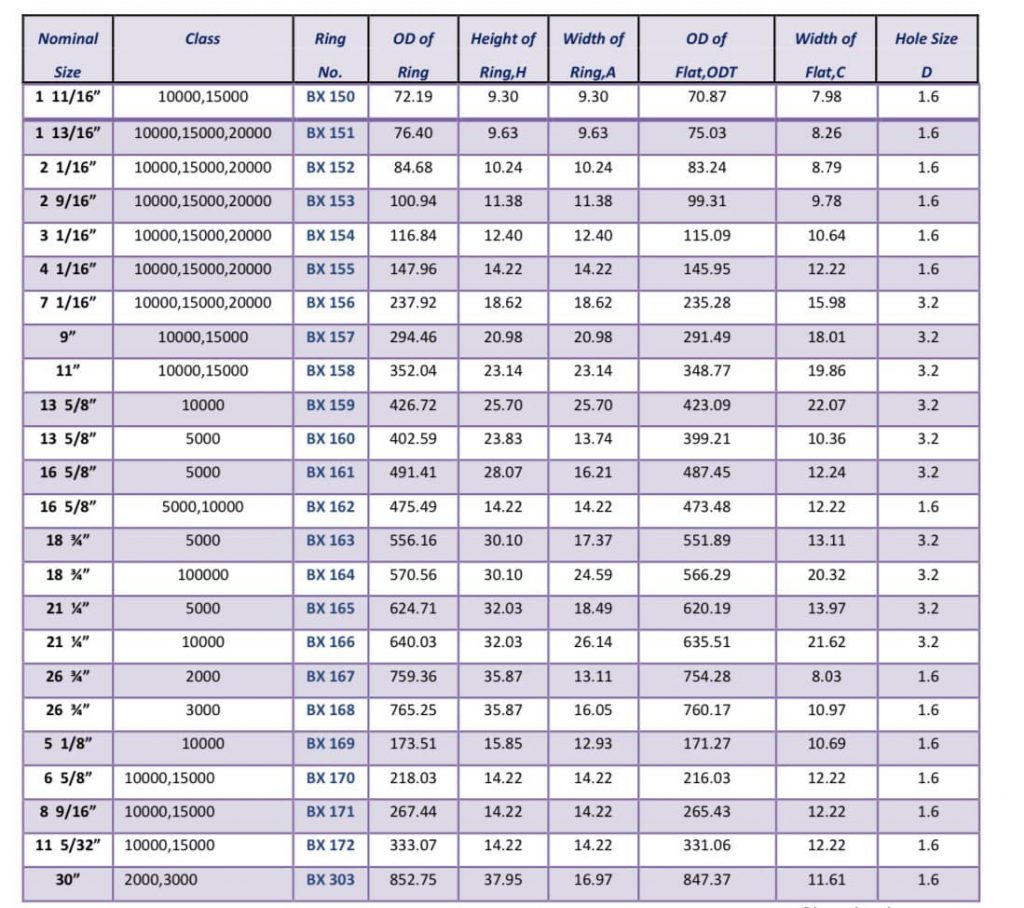

Type BX RTJ Dimensions